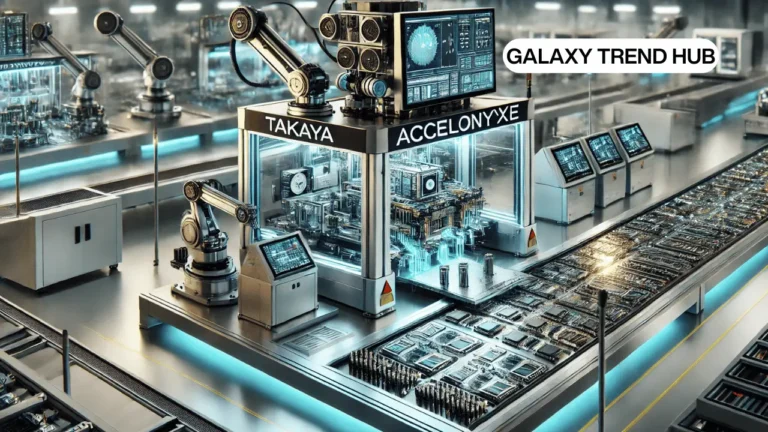

In today’s fast-paced electronics manufacturing world, ensuring quality and efficiency is more critical than ever. Enter Takaya Accelonyxe, a cutting-edge solution designed to transform how printed circuit boards (PCBs) are tested. This advanced system combines high-speed testing capabilities with unparalleled precision, making it a game-changer for industries reliant on flawless electronics. But what makes Takaya Accelonyxe stand out? Let’s dive into the details.

What is the Takaya Accelonyxe?

The Takaya Accelonyxe is an innovative automated test equipment (ATE) system designed to test PCBs quickly and accurately. Its primary function is identifying defects in PCBs used across various industries, including automotive, consumer electronics, and telecommunications. By employing state-of-the-art algorithms and advanced hardware, Takaya Accelonyxe ensures the reliability and functionality of even the most complex PCB designs.

Key Features of Takaya Accelonyxe

One of the reasons Takaya Accelonyxe has gained immense popularity is its impressive array of features. These include:

High-Speed Testing

Takaya Accelonyxe can perform tests in as little as 0.15 seconds per point. This high-speed capability reduces production bottlenecks, enabling manufacturers to meet tight deadlines without compromising on quality.

Exceptional Precision

Accuracy is critical in PCB testing, and Takaya Accelonyxe excels in this area. A positioning tolerance of ±0.5% ensures even the smallest defects are detected, preventing faulty products from reaching the market.

Advanced Testing Algorithms

The system leverages sophisticated algorithms to test various PCB technologies, including surface mount technology (SMT) and through-hole technology (THT). These algorithms allow for comprehensive fault detection and analysis.

User-Friendly Interface

Ease of use is another hallmark of Takaya Accelonyxe. Its intuitive interface simplifies operation, allowing technicians to learn and quickly manage the testing process.

Seamless Integration

Designed with flexibility in mind, Takaya Accelonyxe integrates seamlessly into existing manufacturing systems. This compatibility enhances production workflows and minimizes disruption during implementation.

Applications of Takaya Accelonyxe

The versatility of Takaya Accelonyxe makes it a valuable tool across multiple industries:

Consumer Electronics

From smartphones to home appliances, Takaya Accelonyxe ensures the functionality and reliability of PCBs in everyday devices.

Automotive Industry

The system is crucial in testing PCBs used in electric vehicles (EVs) and advanced driver-assistance systems (ADAS), ensuring safety and performance.

Medical Devices

In the medical field, precision is paramount. Takaya Accelonyxe helps manufacturers meet stringent quality standards for devices like diagnostic equipment and monitoring systems.

Telecommunications

Reliable PCBs are essential for communication devices, and Takaya Accelonyxe ensures they meet the necessary performance benchmarks.

Benefits of Using Takaya Accelonyxe

Enhanced Productivity

Takaya Accelonyxe accelerates production cycles by reducing testing times, enabling manufacturers to bring products to market faster.

Cost Efficiency

Its accuracy minimizes rework and scrap rates, leading to significant cost savings over time.

Improved Product Quality

With its advanced fault detection capabilities, Takaya Accelonyxe ensures only high-quality PCBs proceed to assembly and shipping.

Scalability

Whether for small-scale production or large manufacturing operations, Takaya Accelonyxe seamlessly adapts to varying production needs.

How Takaya Accelonyxe Stands Out in the Market

Unlike traditional testing methods, which can be time-consuming and less precise, Takaya Accelonyxe offers a modern, efficient alternative. Its ability to detect micro-defects and handle high testing volumes sets it apart from competitors, making it a preferred choice for manufacturers worldwide.

Future of PCB Testing with Takaya Accelonyxe

As electronics continue to evolve, so do the demands for quality control. The Takaya Accelonyxe is poised to lead the way in PCB testing, offering advanced features that cater to the increasing complexity of modern PCBs. Its potential to integrate with emerging technologies like artificial intelligence (AI) and machine learning (ML) further solidifies its role in the future of manufacturing.

Common Challenges in PCB Testing Solved by Takaya Accelonyxe

Inconsistent Testing Results

Takaya Accelonyxe ensures reliable and repeatable results, eliminating variability.

Detection of Micro-Defects

The system’s precision allows it to identify even the smallest defects, reducing the risk of failure during product use.

Slow Testing Speeds

With its high-speed capabilities, Takaya Accelonyxe dramatically shortens testing times.

Tips for Manufacturers Implementing Takaya Accelonyxe

- Train Your Team: Ensure technicians are well-trained on the system’s interface to maximize its potential.

- Optimize Workflows: Integrate Takaya Accelonyxe into existing processes for smooth operation.

- Regular Maintenance: Conduct routine maintenance to keep the system functioning at its best.

Conclusion

The Takaya Accelonyxe is more than just a testing system—it’s a transformative tool that enhances quality, efficiency, and reliability in PCB manufacturing. As industries push the boundaries of innovation, the demand for flawless electronics will only grow, making Takaya Accelonyxe an indispensable asset for manufacturers aiming to stay ahead of the competition.

FAQs

What is Takaya Accelonyxe used for?

Takaya Accelonyxe is used for high-speed, precise testing of printed circuit boards to ensure quality and reliability.

Which industries benefit from Takaya Accelonyxe?

Industries like consumer electronics, automotive, medical devices, and telecommunications benefit from its advanced testing capabilities.

How does Takaya Accelonyxe improve PCB testing?

It offers high-speed testing, exceptional precision, and advanced algorithms, solving common testing challenges.

Is Takaya Accelonyxe cost-efficient?

Yes, its accuracy and efficiency reduce rework and scrap rates, resulting in significant cost savings.

Can Takaya Accelonyxe integrate with existing systems?

Absolutely, it is designed for seamless integration with existing manufacturing workflows.